Allturn 110V-100W Plastic Welding Kit,Plastic Welding Iron,Plastic Welding Repair Kit for Car Bumper Dashboard Kayak Canoe Tank Repairs.

$39.99 (as of July 26, 2024 17:22 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Metal sheets make various cutlery sets, window panes, rods, vehicle organs, and multiple things necessary for everyday life and living. Metal sheets are molded and confined to form these daily life necessities. The confinement and molding of these sheets are passed through many heavy-weighted types of machinery. After this passage of events, the pressed metal sheets are bent by applying pressure. Various methods are used to cut aluminum metal sheets.

- Laser cutting.

- Drilling.

- Milling.

- Grinding.

- Framing.

From all these methods, we will discuss the grinding of metal sheets.

Tools used for cutting metal:

Various tools are used to cut those metal pieces, including the following. Cutting metal with small scissors and cutters is not possible. So, these tools are used.

- Tin snips.

- Cuttings sticks

- The Lincoln machines

- Throat shear is reduced.

- Hammer plashing

- Corner notcher.

- Flange and punch tools.

With the help of these tools, the metal sheet is cut down into different sheets and material substances.

Read Recent Post: How to fix the exhaust pipe without welding?

What is the best and easiest way to cut off metal sheets with the abovementioned tools?

The angle grinder provides us with the united, near, and clean joints that professionals require. Let us discuss an angle grinder and how it cuts down metal sheets.

Angle grinder

It is essential to know what an angle grinder is. An angle grinder is a machine with rotating ends that cuts off sheets to manufacture various instruments and household items. It is a hand-held power tool that moves on the surface to grind the unleveled surface, making it smooth, so no dust particles are trapped between the surface when welded.

An angle grinder is used for the following purposes:

- Cutting Sheets, stones, and metals must be cut.

- Giving metal surfaces a finished look

- Grinding uneven surfaces is

polishing the sheet to give it a shine, forming a clean and presentable abstract.

- It also removes rust from metal surfaces.

- Sandling an uneven surface is also the primary use of an angle grinder.

The following is the primary disc used in an angle grinder.

All the discs mentioned above are well established and renewed to maintain the quality of their work and give a shiny, clean, and presentable entity in front of the owner. A rotating wheel disc is primarily used in sensitive edge-forming material cutting. A grinding disc is used to grind down uneven surfaces and make a smooth flat surface placed in front of a viewer. As metal sheets require a significant amount of energy, it is necessary to use a high-quality grinder that can hold voltage changes when applied. Diamond-shaped discs are the most robust grinding discs, giving accurate cutting.

Read More: Welding without mask

How to Use an Angle Grinder

The grinder is mainly used to cut and grind down the pressed metal sheet, so it must be used more efficiently to maintain the look of metal pieces.

For grinding purposes, lift the grinder, switch it on, and let it maintain its full power before applying it to the sheet. So in this way, it cuts down the metal sheet more efficiently and accurately. Then stroke down the grinder on the surface in the direction of the handle rather than moving back north. After doing this, lift the grinder, give it a rest, and repeat the process until the target is achieved.

The following techniques are better used to cut the metal pieces more efficiently.

- Welders should have the proper focus.

- The body should not be the welder’s movement.

- The grinder should be held in the direction of the handle.

- A protective barrier should be between the grinding surface and the person.

Taking all those steps that increase your ability and give you an advantage is essential for better results. Welders usually maintain their body posture and quickly and promptly grasp the technique.

Along with maintaining body posture, they also focus on the machine’s angle and use, which makes them more adapted for success. Hence, canting the grinder can provide better results.

Canting an angle grinder

While holding the grinder, it is necessary to can’t down at a slight angle, giving better vision to a person, which results in the tidy work being finished. Canting the grinder increases the surface area of the grinding edge, providing a better pace for work. The canting of the grinder also corrects the body posture of the welder, giving it a good look and not stiffening his muscles in the neck and back.

Know More About Welding: How to weld exhaust pipes with a stick

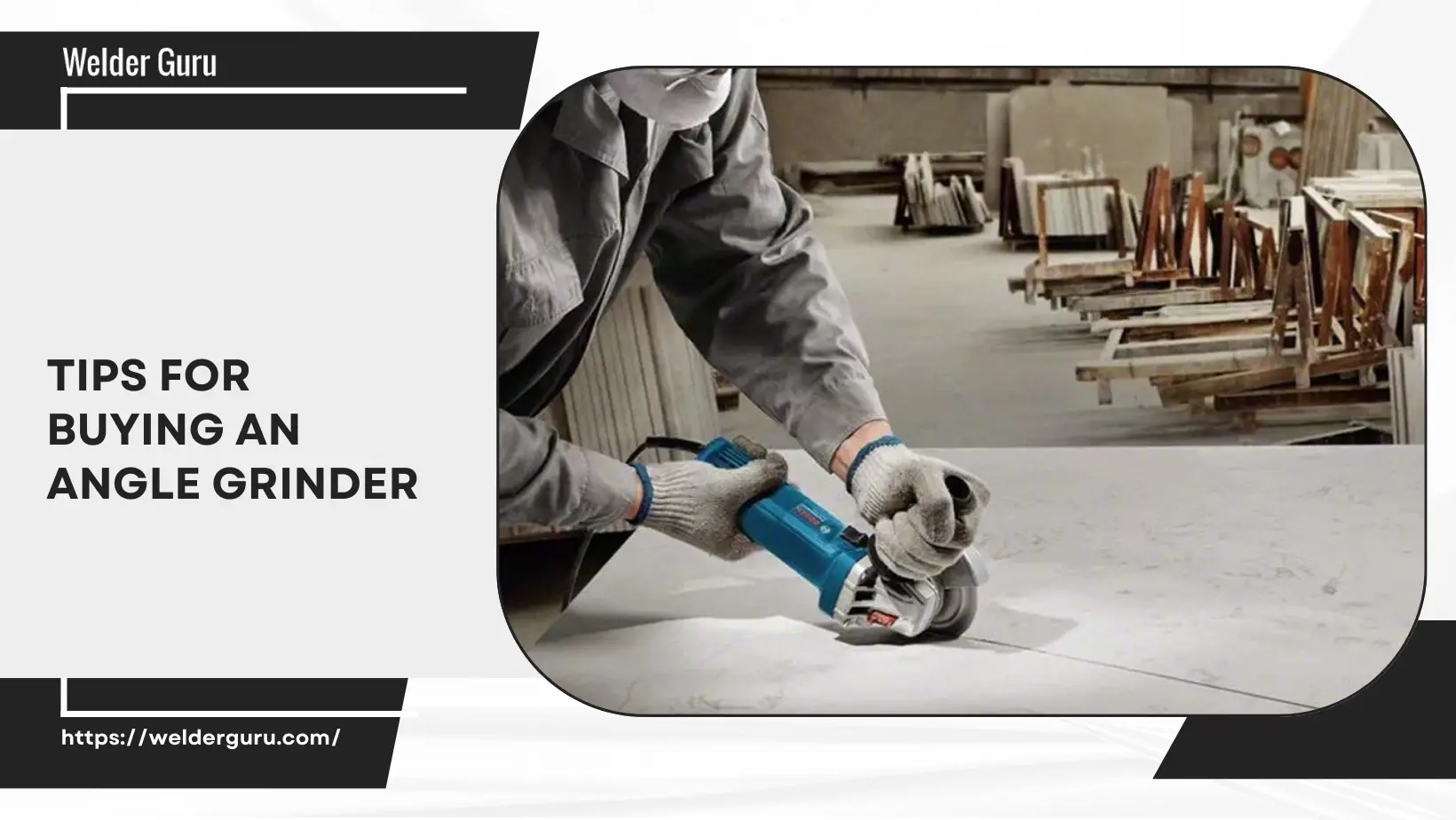

Tips for buying an angle grinder

Buying an angle grinder is not like moving in a park. It also requires a lot of effort and knowledge to buy them.

The following characteristics should be kept in mind while buying the grinder:

- There are several disc sizes available for grinders. For smaller-sized grinders, the disc size of 70 is efficient. The more giant-size grinder is used to achieve accuracy on larger sheets with a thickness of up to 1 inch.

- The voltage and ampere rating of the grinder is also essential because applying the correct voltage will give more accurate work. The grinders with a voltage range between 110 and 220 volts AC can keep the wattage between 500 and 2500 watts.

- Discs having a revolution of 5000 to 10,000 per minute are the way to go, as they are less time-consuming.

From all the above data, metal cutting can be done using an angle grinder. We should have to keep the tricks in our mind for better results. While buying the grinder, every step that makes the angle grinder ancient should be in our minds so no one can deceive us.

Read Other Posts: Best MIG welder under 200

Related Links:

- https://www.wikihow.com/Use-an-Angle-Grinder (By Wikihow) (August 14, 2022)

- https://www.wikihow.com/Grind-Metal (By Wikihow) (September 16, 2021)

- https://www.wikihow.com/Cut-Steel (By Wikihow) (November 24, 2022 )

- https://www.wikihow.com/Use-a-Bench-Grinder (By Wikihow) (March 22, 2021 )

- https://www.wikihow.com/Cut-Corrugated-Metal (By Wikihow) (September 5, 2022 )

- https://en.wikipedia.org/wiki/Angle_grinder (By Wikipedia)

- https://simple.wikipedia.org/wiki/Angle_grinder (By Wikipedia)

- https://en.wikipedia.org/wiki/Disc_cutter (By Wikipedia)

- https://en.wikipedia.org/wiki/Grinding_(abrasive_cutting) (By Wikipedia)

- https://en.wikipedia.org/wiki/Grinding_machine (By Wikipedia)

![YESWELDER 205Amp Stick Welder with Lift TIG Torch, [Large LED Display] 110V/220V Dual Voltage Portable Welding Machine, Digital Inverter IGBT ARC Welder Machine with Hot Start, Arc force #1](https://m.media-amazon.com/images/I/51JhxHKLUEL._SL100_.jpg)

![YESWELDER 205Amp Stick Welder with Lift TIG Torch, [Large LED Display] 110V/220V Dual Voltage Portable Welding Machine, Digital Inverter IGBT ARC Welder Machine with Hot Start, Arc force #2](https://m.media-amazon.com/images/I/51RrNMqW0SL._SL100_.jpg)

![YESWELDER 205Amp Stick Welder with Lift TIG Torch, [Large LED Display] 110V/220V Dual Voltage Portable Welding Machine, Digital Inverter IGBT ARC Welder Machine with Hot Start, Arc force #3](https://m.media-amazon.com/images/I/51VudtlIcxL._SL100_.jpg)

![YESWELDER 205Amp Stick Welder with Lift TIG Torch, [Large LED Display] 110V/220V Dual Voltage Portable Welding Machine, Digital Inverter IGBT ARC Welder Machine with Hot Start, Arc force #4](https://m.media-amazon.com/images/I/41aESAlEJKL._SL100_.jpg)

![YESWELDER 205Amp Stick Welder with Lift TIG Torch, [Large LED Display] 110V/220V Dual Voltage Portable Welding Machine, Digital Inverter IGBT ARC Welder Machine with Hot Start, Arc force #5](https://m.media-amazon.com/images/I/51punp2l1YL._SL100_.jpg)

![ARCCAPTAIN Stick Welder, [Large LED Display] 200A ARC/Lift TIG Welding Machine with Synergic Control, IGBT Inverter 110V/220V Portable MMA Welder Machine with Hot Start, Arc force and Anti-Stick #1](https://m.media-amazon.com/images/I/51QK5h3JmqL._SL100_.jpg)

![ARCCAPTAIN Stick Welder, [Large LED Display] 200A ARC/Lift TIG Welding Machine with Synergic Control, IGBT Inverter 110V/220V Portable MMA Welder Machine with Hot Start, Arc force and Anti-Stick #2](https://m.media-amazon.com/images/I/516PHhn-WrL._SL100_.jpg)

![ARCCAPTAIN Stick Welder, [Large LED Display] 200A ARC/Lift TIG Welding Machine with Synergic Control, IGBT Inverter 110V/220V Portable MMA Welder Machine with Hot Start, Arc force and Anti-Stick #3](https://m.media-amazon.com/images/I/51QmnMXsSDL._SL100_.jpg)

![ARCCAPTAIN Stick Welder, [Large LED Display] 200A ARC/Lift TIG Welding Machine with Synergic Control, IGBT Inverter 110V/220V Portable MMA Welder Machine with Hot Start, Arc force and Anti-Stick #4](https://m.media-amazon.com/images/I/51pPyWmKjWL._SL100_.jpg)

![ARCCAPTAIN Stick Welder, [Large LED Display] 200A ARC/Lift TIG Welding Machine with Synergic Control, IGBT Inverter 110V/220V Portable MMA Welder Machine with Hot Start, Arc force and Anti-Stick #5](https://m.media-amazon.com/images/I/51xVygmJ-iL._SL100_.jpg)