Welding Machine, Upgraded MMA-250A 110V Welder Machine,Portable Stick Welder IGBT Digital Display LCD,Home DIY Arc Welder,Hot Start Arc Force Anti-stick Mini Welder

$78.79 (as of July 10, 2025 19:22 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)This is not unusual for things to break. The need to repair the things are there. This is the reason that many devices to repair the things have been introduced. Welding Machines are one of those.

There are various techniques such as arc welding, semi-automatic welding, and TIG welding. Even many of the welding machines are available. I Honestly think that beginners are worried about which welding machine is suitable for their application. There are several types of welding machines, which are roughly divided into the following three types.

Shielded metal arc welder

Welding rods are set in the holder (the part that is held by hand) and are mainly used for welding iron. Speaking of general welding, this is what is usually done at the outside site by shielded metal arc welding.

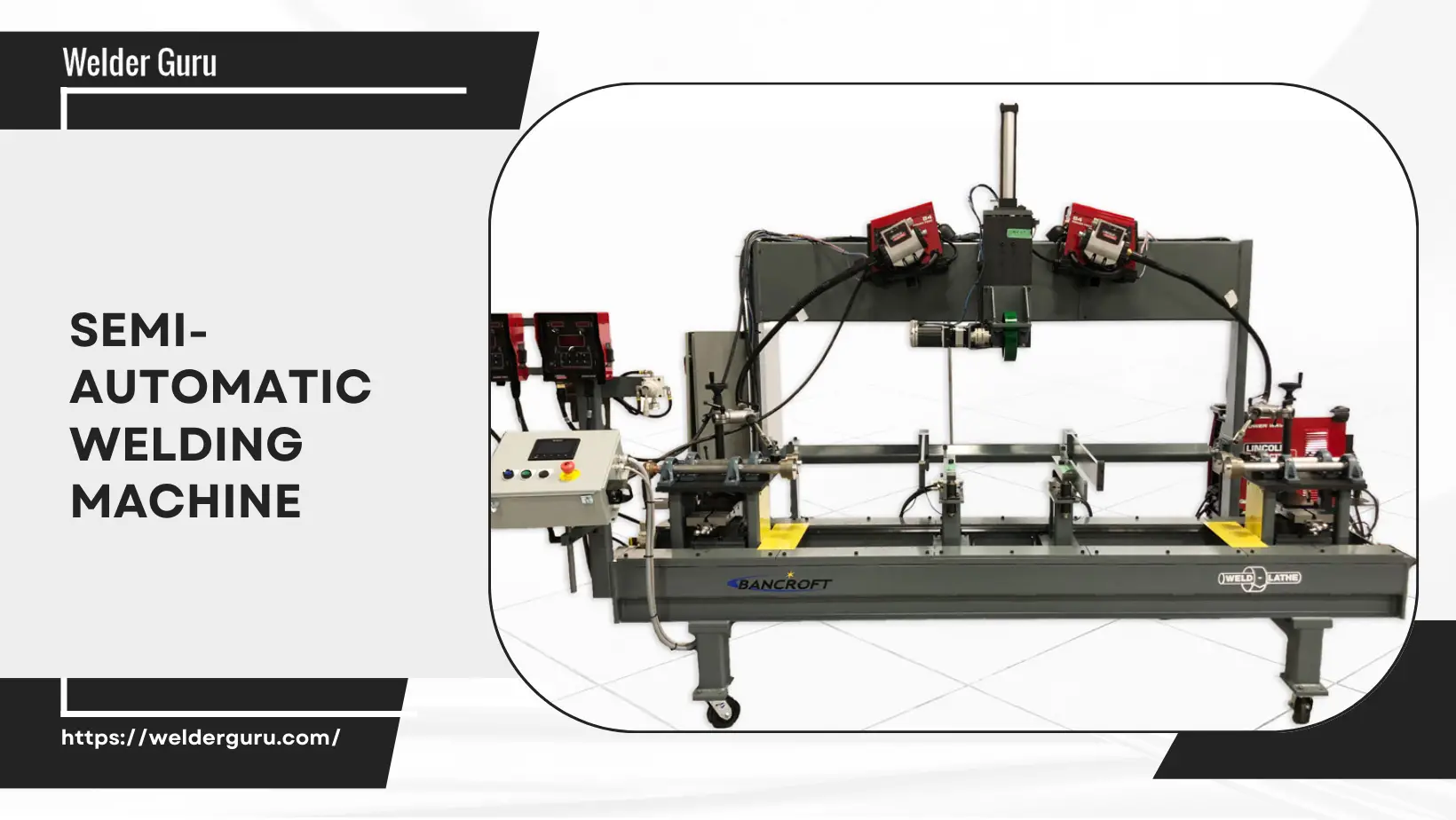

Semi-automatic welding machine

Shielded metal arc welding uses welding rods, while semi-automatic welding uses wires.

When you press the switch on the torch, the wire comes out, and the wire melts and welds the base metal.

It is mainly used for welding iron by connecting carbon dioxide gas, but stainless steel and aluminum can also be welded by changing the wire and gas.

TIG welding machine

It is a completely different type of welding from the above welding and is also called argon welding because it uses argon gas.

As a feature, spatter (sparks) does not fly and it is suitable for welding stainless steel and aluminum.

Welding of iron is also possible, but it is suitable for welding details, and semi-automatic welding is more efficient when welding structures, etc.

Is it a feeling that dig welding is static welding while semi-automatic welding is dynamic welding?

Depending on the welding machine, there are advantages, disadvantages, orientations, and unsuitability, and you may not know which welding machine to use.

Even those of us who sell welders can be confused about which welder to use for this weld.

Therefore, I think that the most suitable welding machine is to select it on two parameters One is the Industry in which you use it and the second is the task for which you will use it.

By the way, when you simply say “welding”, you can think of it as arc welding or any other type of welding. Let us start our journey of exploration with ARC welding.

What is arc welding?

Normally, electricity flows through metal (conductors), right? However, when a high current is passed, the current flows even if there is a gap between the electrodes. This is called arc discharge, and arc welding is exactly the welding method that uses the heat of this arc discharge. In a familiar example, it’s a snap when you unplug the power outlet.

Are there various types of arc welding?

In particular, a method of welding while injecting gas to prevent high-temperature metal from reacting with oxygen in the air and oxidizing is called gas shielded arc welding. It’s like creating a barrier with gas around the metal being welded.

The gases used include inert gases such as argon and helium and mixed gases of inert gas and carbon dioxide (CO2). Gas is injected from the tip of a torch, but it is not suitable for outdoor work because the gas is blown off in a windy environment.

What kind of welding method is suitable for outdoor work?

Shielded metal arc welding and self-shielded arc welding outdoors

We recommend methods that do not use shielded gas, such as shielded metal arc welding and self-shielded arc welding. It is suitable for outdoor work due to its wind-resistant nature.

No, that’s not the case. Instead of injecting shield gas, a filler material (welding rod or welding wire) that is coated with a special powder called flux is used. Using it, when welding is started, this flux is decomposed by arc heat into gas, which protects the welded part and prevents it from oxidizing. In other words, both gas shielded arc and shielded metal arc welding require gas to protect the weld

What are molten and non-polarized types?

In addition, arc welding can be divided into two groups, “welded electrode type” and “non-welded electrode type”. The molten and non-polarized types have the following characteristics.

Welding type:

The electrode itself acts as a welding rod and melts.

Non-welded electrode type: The electrode itself hardly melts. It is necessary to prepare a welding rod separately.

Non-welded

Actually, there are many other things such as submerged arc welding and plasma welding. However, since it requires large-scale equipment and is not used much by individuals, I will omit it here. Then, let’s take a look at each welding method one by one. The first is non-welding TIG welding.

TIG welding (ideal for welding cars and motorcycles)

TIG welding is a welding method that uses tungsten (Tungsten) for the electrodes and an inert gas (Inert Gas) for the shield gas.

Tungsten has the highest melting point (melting temperature) of all metals, reaching 3422 ° C. Therefore, even if this is used as an electrode, it will not melt with arc heat. This is the reason why it is called a non-polar type.

What kind of welding method is it specifically?

The welding rod is melted and welded in the arc formed between the electrode and the base metal (metal to be welded). It has excellent stability and the molten pool can be seen clearly, so it is relatively easy to work, and high quality and clean beads can be drawn. TIG welding is a good choice for welding cars and motorcycles where the appearance is important because the finish is beautiful. However, there is a demerit that the welding speed is slow.

Shielded metal arc welding (ideal for outdoor work)

Shielded metal arc welding is a welding method that uses a welding rod such as Pocky as an electrode to generate an arc between it and the base metal (metal to be welded). The base metal is melted by the arc heat, and the melted electrodes (welding rods) are fused with the base metal. The electrode itself also serves as a welding rod.

Unlike TIG welding, shield gas is not injected.

The coating agent (flux) applied to the welding rod is decomposed by arc heat to become gas, which protects the welded part and prevents it from oxidizing. This coating (flux) also has the effect of stabilizing the arc. Due to its wind resistance, shielded metal arc welding is mostly used for outdoor work. The slow welding speed is a disadvantage

Shielded metal arc welding (hand rod) is explained in detail in this article.

Semi-automatic welding (ideal for a wide range of welding work)

A welding wire is set in the semi-automatic welding machine, and the welding wire is automatically supplied by the wire supply device. However, the welding work itself is manual, so it is called “semi-automatic”.

In shielded metal arc welding (manual welding), it is necessary to replace the welding rod when the welding rod becomes short, but in semi-automatic welding, this is not necessary, so work efficiency is good. Therefore, it is suitable for a wide range of work such as construction sites and maintenance of large vehicles.

Even if you say semi-automatic welding in a bite, it can be further classified according to the type of gas used / not used / gas.

MIG welding

You know it well. First is MIG welding. MIG stands for Metal Inert Gas.

Is it a method of welding metal using an inert gas as the shield gas?

Exactly. Only an inert gas (argon or helium) is used as the shield gas. The finish is beautiful, but the disadvantage is that the arc spreads and the penetration is shallow. Moreover, since argon gas is expensive, it is used only when welding special materials such as aluminum alloy, stainless steel, and heat-resistant alloy steel.

Next is MAG welding? What does MAG stand for?

Abbreviation for Metal Active Gas, which is a welding method for metal, which uses an active gas as the shield gas. A mixed gas of inert gas (argon or helium) and an inexpensive carbon dioxide gas (CO2) is used as the shield gas. By mixing carbon dioxide gas with the inert gas, the arc can be supplemented and energy can be concentrated, and the disadvantage of MIG welding (shallow penetration) can be improved. However, please note that it cannot be used for non-ferrous metals such as aluminum because carbon dioxide causes a chemical reaction.

CO2 welding. Is it a welding method that uses CO2 (carbon dioxide)?

That’s it. As with MAG welding, carbon dioxide causes a chemical reaction and cannot be used for non-ferrous metals such as aluminum, so be careful. Normally, arc welding with carbon dioxide causes more spatter than using an inert gas (mainly argon/helium), resulting in a poor appearance. However, on the other hand, carbon dioxide causes a chemical reaction with the arc, so a repulsive force is generated between the carbon dioxide and the arc, and the arc becomes thinner. As a result, there is an advantage that the heat energy is concentrated and the penetration is deepened.

Self-shield welding (ideal for a wide range of welding and outdoor work)

Finally, self-shield welding. What kind of welding method is this?

So-called non-gas semi-automatic welding. Instead of injecting shield gas, it is a method of using a welding wire coated with flux. Since it does not use shield gas, it is a wind-resistant welding method. It’s like a semi-automatic welding version of shielded metal arc welding.

It’s semi-automatic welding that doesn’t use gas

| Use / do not use gas | Gas type | |

| MIG welding | use | Inert gas (argon / helium) |

| MAG welding | use | Active gas

(mixed gas of inert gas and carbon dioxide) |

| CO2 welding | use | Carbon dioxide (CO2) |

| Self-shielded arc welding | do not use | – – |

Comparison of welding methods

Various welding methods will come out and it will be confusing. I’ve summarized it below, so if you forget it, remember this table!

Comparison of welding methods

| TIG welding | Shielded metal arc welding | Semi Automatic

Welding |

Self Shield Welding | |

| Electrode characteristics | Non-welded | Welding Type | ||

| Material suitable for welding | Mainly stainless steel

(* Aluminum and magnesium are also acceptable for AC ) |

Iron (mild steel) | Iron Mild Steel

Stainless steel and iron can be welded by changing the wire |

|

| Amount of spatter | Few | Many | Somewhat | Many |

| Outdoor use | NG | OK | NG | OK |

| Necessary equipment | Argon Gas | — | Carbon DiOxide Gas | — |

| the expendables | Welding rod, tungsten electrode | Welding rods | Welding Wire | |

How to choose optional parts

Welding cable

When performing shielded metal arc welding, there are many cases where the cable is not attached to the main body. Check the accessories before you buy them.

In most cases, 22 scales are sufficient, but if the current value is high, a cable with a larger cross-section is required. You may consult your electrician or an expert welder before buying.

Welding rods

Select a material that is close to the base material (material to be welded) and a material that matches the capabilities of the welding machine (φ2.6, φ3.2, φ4.0). If there is no material similar to the material, select a welding rod that has the same material properties (tensile, strength, hardness, etc.) as the base material.

Welding rods are greatly affected by moisture, so it is important to dry them thoroughly before use.

Welding helmet

Direct exposure to the intense light generated during welding can cause UV-induced corneal inflammation and infrared-induced retinal and corneal burns. Chronic exposure to direct welding light can lead to cataracts and damage to the retina. It is perfect if you also use protective goggles.

Since the shading degree number to be used changes depending on the welding current value, it is necessary to confirm whether the shading degree is within the range before purchasing.

Light-shielding protective equipment specifications Standard (JIS)

| Shading degree number | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| Welding current value (A) | 30-75 | 76-200 | 201-400 | ||||

Welded shoes

With ordinary safety shoes, there is a risk that the mesh part will melt due to spatter and cause burns. When welding, use leather welding shoes that have excellent heat resistance and prevent deterioration due to high temperatures.

Final Words

That’s how to choose a welding machine. How was that? If you have any questions, please feel free to post them in the comments section.

Related Links:

- https://www.wikihow.com/Become-an-Underwater-Welder (By Wikihow) (August 20, 2022 )

- https://www.wikihow.life/Choose-a-Hammer (By Wikihow) (August 5, 2022 )

- https://www.wikihow.com/Adjust-a-Welding-Machine (By Wikihow) (December 8, 2020 )

- https://www.wikihow.com/Weld-Copper (By Wikihow) (November 30, 2022 )

- https://www.wikihow.com/Become-a-Metal-Fabricator (By Wikihow) (November 20, 2020 )

- https://en.wikipedia.org/wiki/Welder_certification (By Wikipedia)

- https://en.wikipedia.org/wiki/Arc_welding (By Wikipedia)

- https://en.wikipedia.org/wiki/Gas_tungsten_arc_welding (By Wikipedia)

- https://en.wikipedia.org/wiki/Welding_joint (By Wikipedia)

- https://en.wikipedia.org/wiki/Exothermic_welding (By Wikipedia)