Portable Handheld Welding Machine - 110V IGBT Inverter Handheld Welder, 20-120A Portable ARC Welder, Hot Start & Anti-Stick for 3/32"-1/8" Welding Rods, Father's Day Gift for Men(Grey)

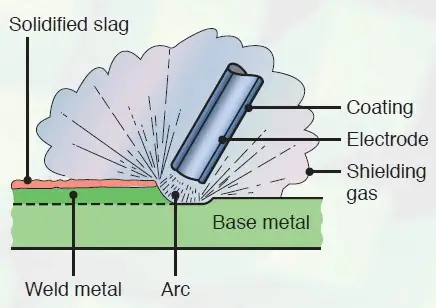

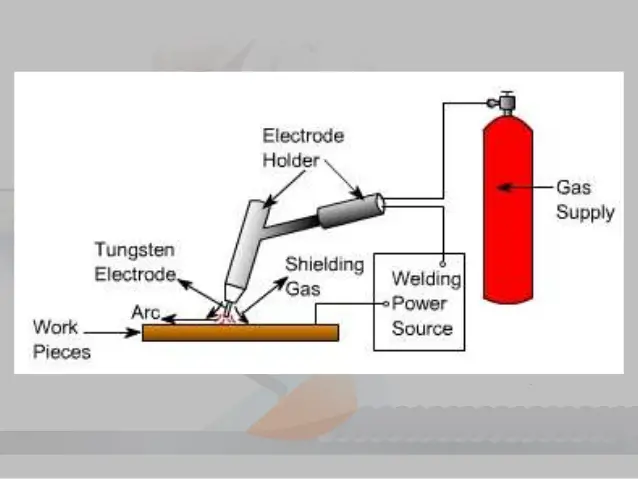

43% OffThe process of tig welding is done through the tungsten electrode of non-consumable nature. The welding can be done in both ways with the filler Mattel or without the filler Mattel. The welding equipment is of three types. These are MIG, TIG, and stick. The Stick and the TIG welder resemble each other while the MIG welding machines are different in many aspects. The TiG welder set up is not a difficult task to do.

All you need is to have a good idea about the different parts of the Tig welder and the mechanism to get it ready.

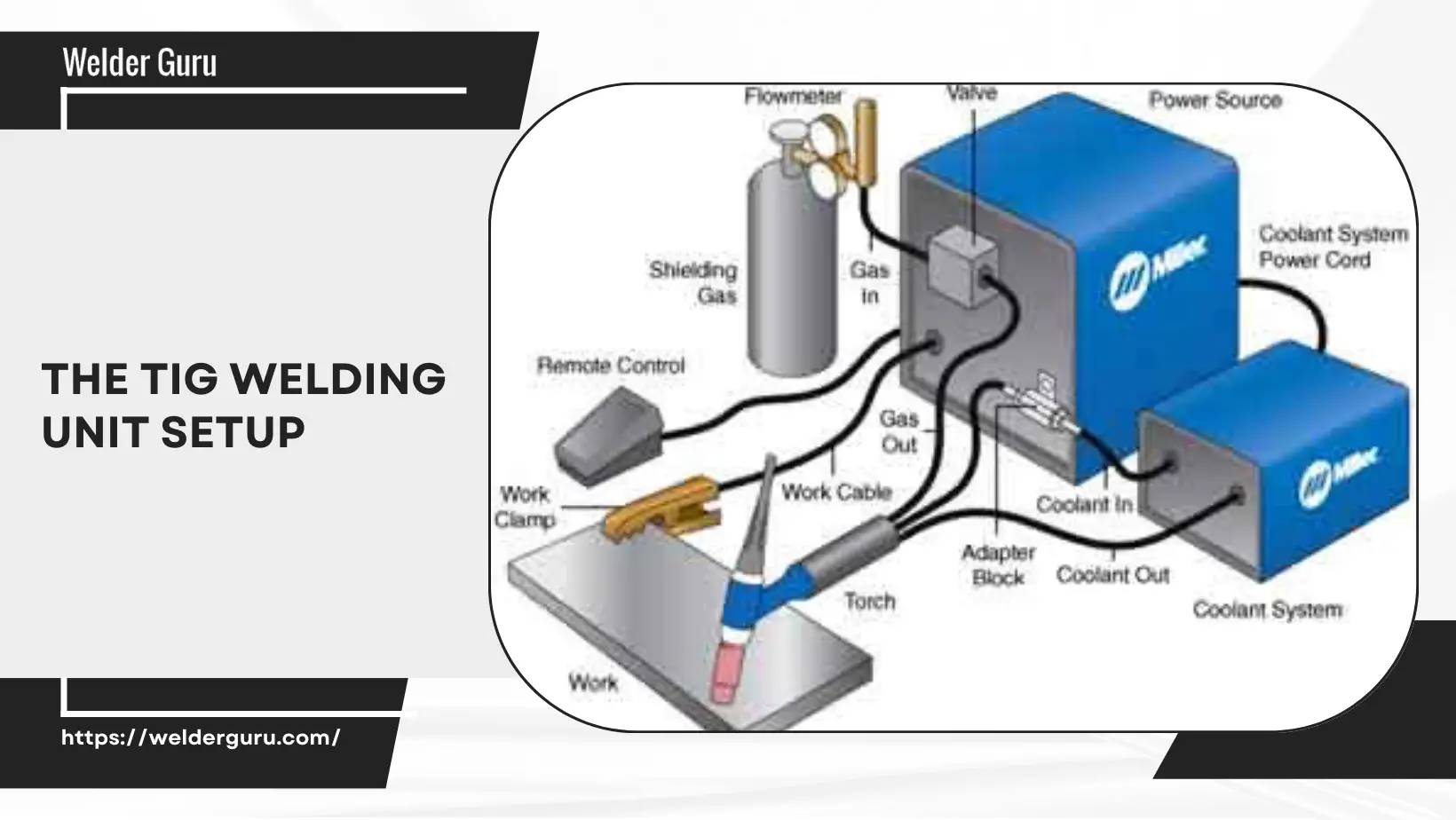

The TiG welding Unit Setup

Tig welding unit can be of multiple types. There can be many accessories included. What we are doing here is to discuss the most basic equipment here. This equipment is present in all Tig Welding units. So this will be easy for you to set up any of the Tig welding units. The most basic type of TiG welder includes

The Electrode

Every TiG welding machine has an electrode. This electrode is of the Tungsten type.

Tig Electrodes

The TiG electrode is classified on two different basis one is on the basis of variations and the other is on the basis of finish

Variation Based Classification

- The first available choice electrode of pure tungsten. The first advantage of this type of electrode is that it is less expensive. Other than this advantage the disadvantages are more in numbers. Like the current carrying capacity of this type of electrode is really low. The second thing is the contamination. The contamination rate is relatively high. It means that this type of electrode can be easily contaminated. Two elements thoria or zirconia if added can significantly improve the current conduction through this pure tungsten electrode.

- The second choice is to add thoria with the pure tungsten. This addition should not be less than 1% and more than 2%. This clearly improves the capacity of carrying current. It also adds in the shape stability, reduces the chances of being contaminated. Arc strikes well with this composition.

- The third choice is nearly the same composition but this time the Pure Tungsten is not so sure this is the mixing of 1 or 2% thoria with the Tungsten. This is a highly reliable electrode. It has been used at the places where the risk element is really very high. Like for the welding purposes in the airplane and even in the nuclear reactors.

- The electrode is made with the Zirconia mixing in Tungsten. This mixing is usually as high as 0.40% and as low as 0.15%. This combination provides more options to work with than pure Tungsten and tungsten with the thoria.

- The second type of classification is on the basis of electrode finishing. Two types of electrodes available with this type of classification. One is clean Finish and the second is centerless ground finish.

- Electrode with the clean finish

This has a smoother surface with almost no defects. Multiple types of weldings can be done easily with this type of electrode - Electrode with the ground finishes centerless. This is best for jobs that require a superior finish to complete.

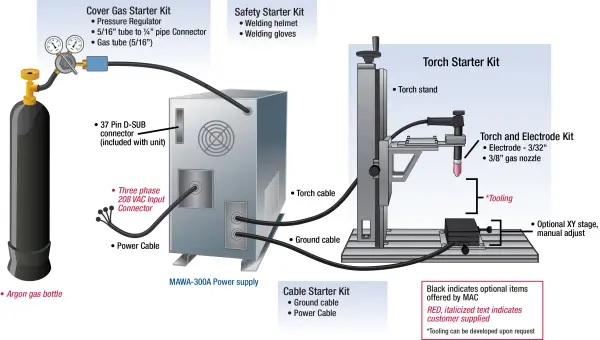

Welding machine

This welding machine can be of different times as far as the classification on the basis of current is concerned. This can be of constant current CC. It can be of AC, or DC or AC DC both

Torch

The touch is the holder of the electrode. This helps the electrode to achieve a high temperature. At this high temperature, the metals can be melted to create a joint between them.

Gas Supply

Multiple types of gases are available for the welding units. These gases are shielded gases. Three different types of mixtures are available. These are argon, helium, and the mixture of both. These three types of mixture serve different purposes.

Like the Argon gas is best to weld the thinner metals. This gas does not produce so high a temperature that it can damage the metals. The topic of the gas supply with the advantages and the disadvantages of both the gases and the mixture will be letter discussed in this article in detail

Argon Gas

The purpose to use this gas is to be operated at a comparatively low temperature. This will make it possible to weld the thinner metals. At high temperature, the thinner metals can be damaged. To save the thinner metals the gas is the best choice. This can make the welding possible at a comparatively low temperature. Some more advantages other than this to use the Argun gas as the welding gas ae

- This is a cheaper choice in comparison than page

- This gas is heavier than the air, heavier gas is both an advantage and a disadvantage. This is an advantage as it is easy to control the heavier gases while welding. This heaviness becomes a problem when you are welding at a point that is situated above your head.

- The arc voltage is low this means that the metals that can be destroyed completely or partially damaged can be easily managed with this gas.

- The stability of the ARC is impressive. This provides better control and precision in the process of welding.

- The cleaning is easy and can create good results

- Arc voltage is lower in comparison to the other alternative available gas substitute.

- The Aircon used with the argon gas is focused

- The flow rate measured in the CHF is minimum 10 and maximum 30

- The Arc is stable even from the start.

Helium Gas

This is an alternative gas that can be used in the welding of the thicker metals. The thicker metals require high temperatures for the welding process. This high temperature can be easily obtained with the helium gas

- This gas is not at all good while operating at the low amp. Even the arc is not stable at a low temperature.

- The helium gas is able to provide you with better penetration

- The cleaning action is not required so frequently

- Arc cone is flared

- The arc voltages are comparatively higher

- The flow rates are also comparatively higher. Approximately double than the other available choices

- Arc is difficult to start and manage in the beginning.

- In comparison to the other available alternative, the Helium gas is expensive but it provides its own unique capabilities

- The traveling speed is comparatively higher than the other available alternatives.

The Mixture of Argon and Helium Gas

The mixture is made to cover the disadvantages of using the Helium and Argon booth. Naturally, both gases have a disadvantage. The mixture will help to cover some of the weaknesses of each gas with the strength of the other gas.

- The mixture will be of higher cost in comparison with the Argon alone

- The mixture provides a better travel speed in comparison to using the Argon alone.

- The penetration rate of the mixture is high in comparison with the Argon gas alone

- The flow rate is also higher in comparison to the Argon only

- The cleaning properties are nearly the same as like the Argon gas

- Arc starting is clearly improved in comparison to the Helium gas alone

- The Arc is more stable in comparison to the helium gas alone

- The shape of the ARC is more focused in comparison to the Helium gas alone

- The arc voltage is more than the Argon but less than the helium.

NOTE FOR THE DESIGNER ADD A BOOKMARK HERE FOR THE USER TO REACH AT THE GAS SUPPLY LINK AT THE LAST PORTION OF THE ARTICLE

Filler Metals

This is the metal that will fill the joint between the two metals. In TiG welding machines this is in the form of the rod. These rods should be ready and an important part to set up the Tig welder.

The Criteria Select the Tig Equipment

The selection criteria for any tool, technical or non-technical entr=irely depends on your need. The matching of the needs with the available properties to fulfill the needs will result in the form of the perfect tool for your needs to work with.

Some criteria that are used for the selection of the TiG welding equipment are:

The shape of the electrode

The use of the electrode is subjected to be in the proper shape and size. This is necessary for the electrode to fit it into the electrode cap. Some jobs can be done only with the electrode of a specific type. This electrode must be of specific size and shape

The electrode can easily be converted into a specific shape. The equipment used for this specific purpose is a hammer, pliers, and wire cutters. Two shapes are generally used the first is the square and the second is the blunted edge.

Working with the DCSP type of current a sharpened edge electrode in the shape of pointed nib is needed. If you are working with the AC type of the current then you will need the electrode with the rounded edge.

The amperage of welding Machine

This is the output capacity of the current. The power with which the machine will weld the metals and create a joint between the metals. High amperage is required for the heavier metals. On the same hand, this high amperage will destroy the surface of the thinner metals too.

Depending on the metals to work with you should select the amperage of the welding machine. The good thing is that the welding machines with multiple output amperage are available. You may select the desired output level to work with.

Type of Current of the welding Machine

The popular choice is the DC current for the welding machine. Although not as popular as the DC current the AC current machine has its specific edges too. Especially some specific metals can only be welded through the AC current machines only.

A good thing is that machines with variable current choices are available. You may choose to work with your desired one. In this way, you can take the benefit of the functionalities of both.

The Gas to be used in The welding machine

Three Different types of gases are available to be used in the welding machines. Check if the welding machine can work with your desired type of gas or not. The Gas details are available in this article

kEEP IN MIND

NOTE FOR THE DESIGNER ADD A BOOKMARK HERE FOR THE USER TO REACH AT THE GAS SUPPLY LINK PORTION OF THE ARTICLE

Optional Features through Additional Accessories

If you buy additional accessories you can take the benefit of many optional features. These optional features can help you to do the welding easily. Some examples of these accessories are foot rheostat, arc timer, and water circulating systems.

The foot rheostat is used to control the current at the run time. This means that you can control the flow of the current during the process of welding. The water circulation system helps you to cool down the machine. As rapidly as the machine cools down the next process of the welding can be started easily.

If the water cooling down unit is automatic. The water flow will be automatically started as soon as the temperature reaches near the critical point. As soon as the temperature decreases to reach well in the safe zone the flow of the water will be stopped.

Final Words on Set up a Tig Welder

Setting up a Tig welder unit is not a difficult task but rather the technical one. We need to set multiple parameters accordingly. Above we have comprehensively discussed all the required parameters to be arranged for the set up of the Tig Welder. If you do not know about the parameter. The equipment to control that parameter or to be controlled by this parameter. You will never be able to set it up properly. This has been advised that you should know each and every detail of this. This detail has been comprehensively described in the above lines. Have a look and make your life easy.

The last thing here but the first thing while setting up the welding machine is protection. Do due care and take preemptive measures before starting welding. Be vigilant and remain safe.

Related Links:

- https://www.wikihow.com/TIG-Weld (By Wikihow)

- https://www.wikihow.com/Weld (By Wikihow)

- https://www.wikihow.com/Adjust-a-Welding-Machine (By Wikihow)

- https://www.wikihow.com/Become-a-Welder (By Wikihow)

- https://www.wikihow.com/Category:Welding (By Wikihow)

- https://en.wikipedia.org/wiki/Gas_tungsten_arc_welding (By Wikipedia)

- https://en.wikipedia.org/?title=Tig_welding&redirect=no (By Wikipedia)

- https://en.wikipedia.org/wiki/Welding (By Wikipedia)

- https://en.wikipedia.org/wiki/Gas_metal_arc_welding (By Wikipedia)

- https://en.wikipedia.org/wiki/Spot_welding (By Wikipedia)